With the New Year, new hose may be needed.

Happy New Year from Amazon Hose & Rubber Company! The beginning of a new year always brings new opportunities and your partners at Amazon are here to help you maximize the use of your time and resources.

Something to consider in any Hydraulic or Industrial system is that the hose components have the highest wear. With that in mind, Amazon Hose recommends beginning the new year with inspecting your hose and fittings in all applications. Below are some examples of warning signs of wear that may cause a system failure:

Abrasion

Abrasion

Problem: The hose has obvious external wear with parts of the cover missing.

Cause: This is caused by the hose being subjected to excessive rubbing and abrasion. This will lead to premature failure of the hose assembly.

Solution: Replace the assembly and include an abrasion guard.

Weathering

Problem: The cover of the hose is discolored and shows signs of cracking.

Cause: This is caused when the hose exceeds extended service in the outdoor conditions and has been damaged by UV and temperature extremes.

Solution: Replace the hose assembly and inquire if there is a product that will mitigate UV exposure.

Install Date

Problem: The hose has burst, and wire reinforcement has failed in the braid along the outside of the hose — with little, if any, outward deflection of wire in the failed area.

Cause: The hose exceeded its service life, perhaps as a result of a high number of pressure cycles or a continuous flexing of the hose in one area. This hose has simply outlived its useful life.

Solution: Review the application and replace the assembly.

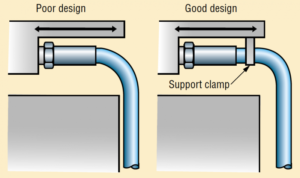

Hose Routing

Problem: The hose shows wear or kinking at a bend near the ends.

Cause: This is caused by improperly routing the hose, which results in premature wear near the fitting and will cause a failure at that point in the assembly.

Solution: Replace the hose and combine with a 45 degree or 90 degree adapter or a support clamp to remove the stress where the hose is coupled.

Implementing an ongoing inspection and maintenance program is well worth the time and effort. Doing so will help you learn from premature failures, to prevent them in the future. Some locations may require a monthly inspection, while others may need more frequent inspection. Operating conditions for hose on machinery can vary tremendously — even within the same project. There probably will be differences in operating pressures, pressure-cycling, fluid temperatures, or even fluids. Thus, the people best qualified to accurately assess how often to check the equipment are usually the people on site.

Due to the wide variety of operating conditions and uses for hose and fittings, Amazon Hose and our vendor partners offer a variety of solutions designed ensure that your projects run smoothly and your team members work safely. This general guide does not analyze all technical parameters, hoses should always be inspected prior to installation and use.

The Amazon Hose & Rubber Company team is here to help you work safely in the New Year, as well as provide you with the best possible solution to avoid system failure and downtime. We are ready to help you with product inspection or replacement. Visit our website at amazondev.wpengine.com or call us at (800) 506-5514.